|

To make silage, the farmer first cuts the grass with a mower. The mower, which is powered by a tractor, will often incorporate a mechanism which encourages the grass to wilt. This type of mower is known as a mower conditioner. Wilting is important because this removes excess moisture from the grass. This reduces the volume of the material to be transported. It also minimises the amount of noxious effluent produced by the silage. |

|

Some farmers will spread the grass to achieve a better wilt. It will then be gathered into rows so that the harvesting machine can pick up the grass. The grass will not be allowed to dry too much as this interferes with the fermenting process. It also makes it more difficult to expel the air from the crop. This is necessary in order to allow fermentation to take place.

|

|

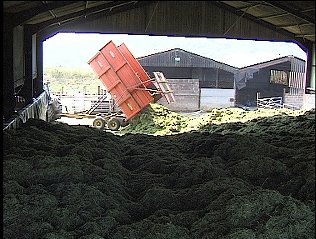

There are two methods of making and storing silage, round baling and precision chop harvesting. In the former, the grass is allowed to wilt longer. A machine called a Round Baler is then used to roll the grass into large round bales of about 1.5 metres in diameter. The bale (left) is then wrapped in plastic by a wrapping machine and stacked for use in the winter. The plastic wrapping prevents air from entering the silage and provides good weather protection. Because of this, bales can be stacked outdoors, even on the side of fields. |